TPE Knowledge

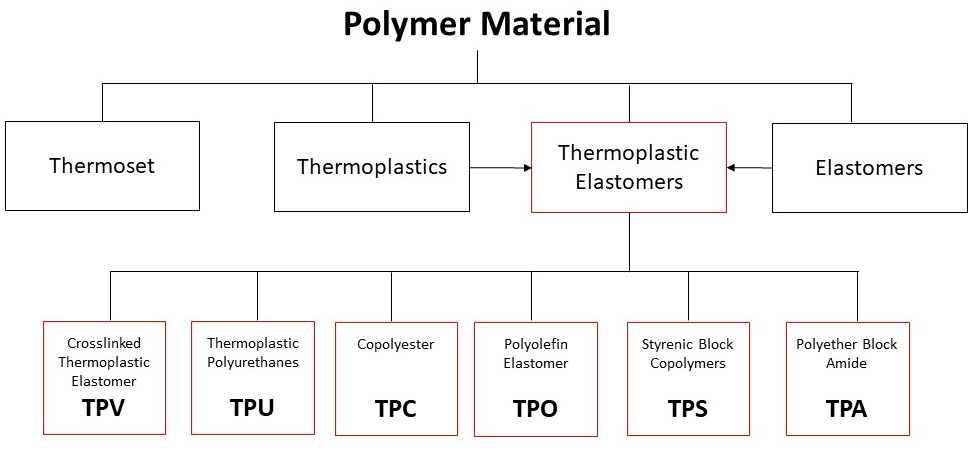

Thermoplastic elastomers are a special category of polymers that have the processability properties of plastics along with the softness and flexibility of rubber. This kind of polymer is designed in order to achieve the desired properties along with making the processing easier.

The different types of TPE

TPE Processing

Like thermoplastics, TPEs are heated to process them by means of injection molding or extrusion. As they show their original elastic properties again after cooling down, they are recyclable like thermoplastics. In contrast to TPEs, elastomers cannot be processed by melting; they are chemically crosslinked and not recyclable.

Favor of using TPE

- Easy processing like thermoplastics

- Short production cycle time

- Reducing the production cost and the energy used for production

- Can be combined with different materials

- Recyclability

- Effective colorability and formability in the appearance of the final product

- Wide field of consumption in various industries

Polymer alloys:

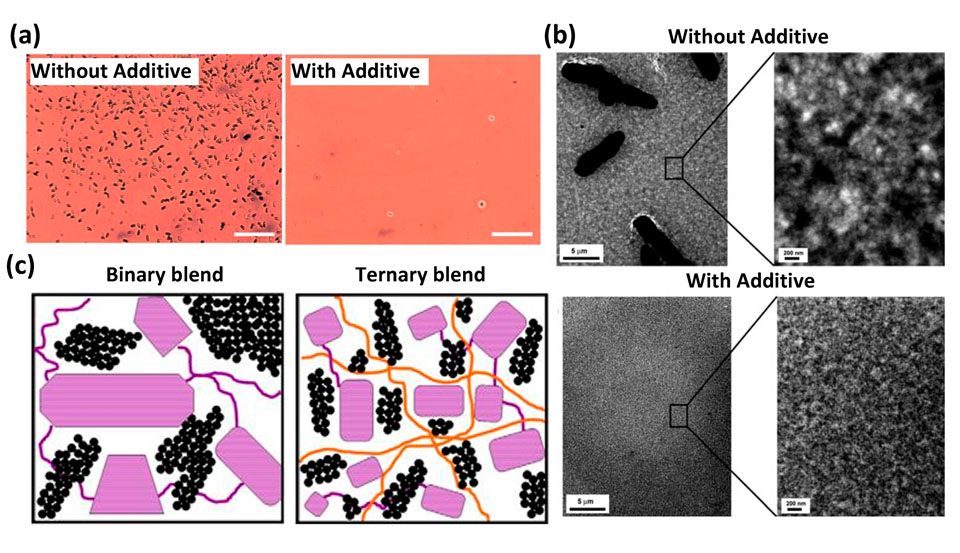

The combination of two or more polymers is called the alloying process that make a new polymer with unique properties. The words alloy and polymer blend are often used together. A polymer blend means mixing at least two types of polymers or copolymers or a combination of several additives with a polymer base, but a polymer alloy is a heterogeneous mixture of polymers that is produced by surface modification processes or a compatibilizer.

The polymer alloy properties is designed by the structure and substructural composition of molecular chains and its morphology. Factors such as process conditions create different structures, each gives unique properties.

In general, if a compatible morphology is created, we can see desirable properties based on the properties of their own polymers, which creates unique properties of a new polymer without the need for synthesis.