Ternary blend morphology

01 June 2024

Morphology is determined by parameters such as surface tension, composition ratio of components, viscosity of components and process conditions. The combination of components and surface tension can be described as two main factors. The purpose of many researches in the field of ternary blend is to establish a relationship and between the mechanical properties and the morphology of the polymer so that it is possible to predict the final mechanical properties.

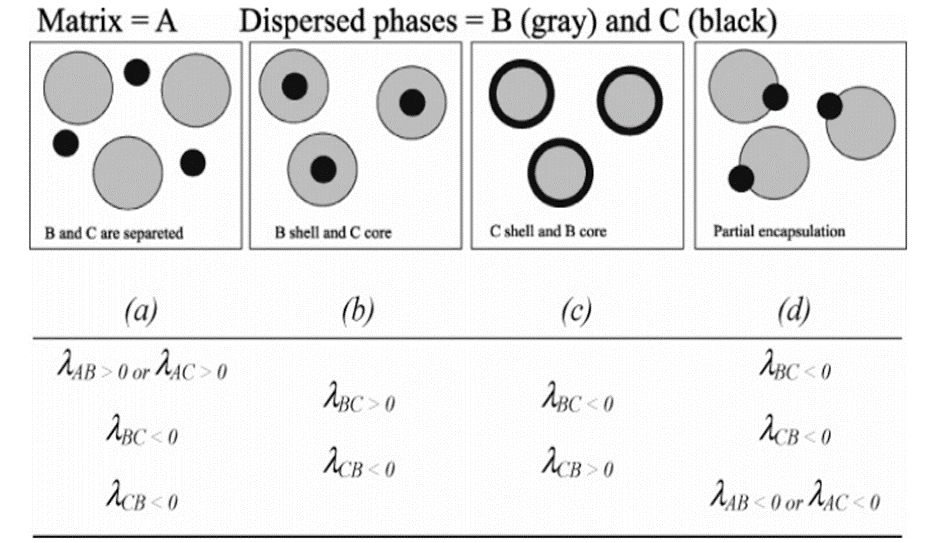

For ternary blend, three types of morphology can be determined:

- Separate particles: two non-primary phases are placed in the matrix phase as separate drops.

- Core-Shell: in such a way that one phase is encapsulated by another surrounding phase. This depends on the surface tension of the two polymers.

- Partial encapsulation: they are partially connected to each other and complete encapsulation does not occur.

imagine we have a binary system consisting of two immiscible polymers. These two polymers will have two separate phases in their microstructure, in such a way that the main phase shows itself as a matrix and the other phase with particles dispersed in the matrix phase. The main origin of the formation of these two phases can be considered the difference in surface energy between these two polymers.

Harkins spreading coefficient morphology prediction

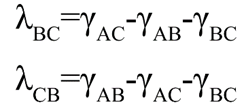

Harkin's coefficient is one of the morphological prediction relations of ternary systems. According to the following relationship, if the diffusion coefficient of phase B on phase C, which is the result of the difference in surface tension of the diffusing phases with the matrix phase and also has positive values, it will be phase B that will surround phase C. Similarly, if the diffusion coefficient of phase C on phase B has positive values, it is phase C that will surround phase B.